Introduction

Earthing practices adopted at Generating Stations,

Substations, Distribution structures and lines are of great importance. It is

however observed that this item is most often neglected. The codes of practice,

Technical Reference books, Handbooks contain a chapter on this subject but they

are often skipped considering them as too elementary or even as unimportant.

Many reference books on this subject are referred to and such of those points

which are most important are compiled in the following paragraphs. These are of

importance of every practicing Engineer in charge of Substations.

Importance of Earthing & Practices

The earthing is provided for

a) Safety of Personnel

b) Prevent or atleast minimise damage to equipment as a

result of flow of heavy fault currents.

c) Improve reliability of Power supply

The earthing is broadly divided as

a) System earthing (Connection between part of plant in an

operating system like LV

neutral of a Power Transformer winding and earth).

b) Equipment earthing (Safety grouding)

Connecting

frames of equipment (like motor body, Transformer tank, Switch gear box,

Operating rods of Air break switches, etc) to earth.

·

The system earthing and safety earthing are

interconnected and therefore fault current flowing through system ground raises

the potential of the safety ground and also causes steep potential gradient in

and around the Substation. But separating the two earthing systems have

disadvantages like higher short circuit current, low current flows through

relays and long distance to be covered to separate the two earths. After

weighing the merits and demerits in each case, the common practice of common

and solid (direct) grounding system designed for effective earthing and safe

potential gradients is being adopted.

·

The earth resistance shall be as low as possible

and shall not exceed the following limits:

Power Stations - 0.5 Ohms

EHT Substations - 1.0

Ohms

33KV Stations - 2.0 Ohms

D/t Structures - 5.0 Ohms

Tower foot

resistance - 10.0 Ohms

Step Potential

Step Potential

is the difference in the voltage between two points which are one metre apart

along the earth when ground currents flowing.

Touch Potential

Touch Potential

is the difference in voltage between the object touched and the ground point

just below the person touching the object when ground currents are flowing.

Specification of Earthing

Depending on

soil resistivity, the earth conductor (flats) shall be buried at the following

depths.

Soil Resistivity in ohms/metre Economical depth of Burial in

metres

1) 50 – 100 0.5

2) 100 – 400 1.0

3) 400 – 1000 1.5

To keep the earth

resistance as low as possible in order to achieve safe step and touch voltages,

an earth mat shall be buried at the above depths below ground and the mat shall

be provided with grounding rods at suitable points. All non-current carrying

parts at the Substation shall be connected to this grid so as to ensure that

under fault conditions, none of these part are at a higher potential than the

grounding grid.

Plate Earths

·

Taking all

parameters into consideration, the size of plate earths are decided as

Power Stations & EHT Station - Main

- 100

x 16mm

Auxiliary

- 50 x 8mm

Small Stations - 75 x 8mm

·

The complete

specifications for providing earth mats at EHT & 33KV Substations,

Distribution transformers & Consumers premises are reproduced below.

Specification for Earthing System

I) EHT Substation

1. The earth mat shall be as

per the approved layout. The earth mat shall be formed with the steel flats

buried in the ground at a depth of 750mm on edge.

2. The earth mat shall extend

over the entire switchyard as per the layout.

3. All the junctions of the

steel flats while forming the earth mat and taking risers from the earth mat

for giving earth connections to equipment, steel structures, conduits cable

sheaths shall be properly welded. All joints shall be provided with suitable

angle pieces for proper contact between flats.

4. Provisions shall be made for thermal expansion of the

steel flats by giving smooth circular bends. Bending shall not cause any

fatigue in the material at bends.

5. The earth mat shall be formed by welding 50x8 mm steel

flat to the 100 x 16mm peripheral earth conductor. The grounding grid shall be

spaced about 5 meters i.e in longitude and about 5 meters in the transverse

directions. After the completion of earth mat, the earth resistance shall be

measured. In case the earth resistance is more than one ohm the earth mat shall

be extended by installing extra electrodes, so that the earth resistance is

less than one ohm.

6. All fence corner posts and gate posts shall be

connected to the ground by providing 32mm dia M.S rods of 3 metre length near

the posts and connected to the main grounding mat.

7. All paint enamel and scale shall be removed from

surface of contact on metal surface before making ground connection.

8. The risers taken along the main switchyard structures

and equipment structures (upto their top) shall be clamped to the structures at

an interval of not more than one metre.

9. 50 x 8mm ground conductor shall be run in cable routes

and shall be connected to the ground mat at an interval of 10 metres.

10. Grounding electrodes of 32mm dia 3mtr. long MS rods

shall be provided at the peripheral corners of the earth mat. The grounding

rods shall be driven into the ground and their tops shall be welded to clamp

and the clamp together with the grounding rods shall be welded to the ground

mat.

11. Lightening arrestors shall be provided with earth pits

near them for earthing.

12. Cast iron pipes 125mm dia and 2.75 metres long and

9.5mm thick shall be buried vertically in the pits and a mixture of Bentonite

compound with Black cotton soil a ratio of 1:6 is to be filled 300 mm dia and

the pipe for the entire depth. Where it is not possible to go to a depth of

2.75 metres, 1.3 x 1.3 MMS plates, 25mm thick shall be buried vertically in

pits of 2 metres depth and surrounded by Bentonite mixture atleast 2 metre away

from any building or structure foundation. The plates shall be atleast 15

metres apart. These earth pits in turn shall be connected to the earth mat.

II) Earthing at 33KV Substations

1.

Providing of earth pit and earth matting include the following connected works:

a) Excavation of earth pits of size 21/2ft x 21/2ft x 9ft

in all type of soils.

b) Providing of CI pipe of 3 inch diameter 9ft length

with flange. All connections to CI pipe shall be with GI bolts and nuts.

c) Filling of earth pit excavated with Bentonite with

Black cotton soil (1:6) in alternate layers.

d) Providing of cement collar of size 2ft diameter 2ft

height 1 inch below the ground level.

e) The top of the CI earth pipe should be at the surface

level of the ground.

2. Providing of

earth matting with MS flat 75 x 8mm including the following connected works:

a) Excavation of trench in all types of soils of size 2½

ft depth and 1 ft. width.

b) Laying of M.S flat 75 x 8mm in the excavated trench.

c) Inter connecting all earth pits and welding properly

at jointing location and junctions.

d) Back filling of earth completely.

III) Earthing at Consumer’s premises

The earthing at Consumer’s premises shall be as

per sketch below using a 6mm thick plate

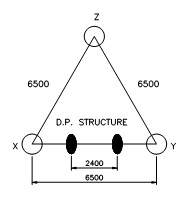

IV) Earthing at D/P Structure

Three

electrodes forming an equilateral triangle with minimum distance of 6500 mm, so

that adequate earth buffer is available. Each Electrode shall be ‘A’ grade GI

pipe of 2 inch thick and 8ft long and buried vertically so as to leave about 4

inch pipe length above ground level to fix a ‘U’ shaped clamp.

Note:

1. The connections to the three earth conn.Electrodes

should be as follows.

(A) To one

of the earth electrodes on either side of double pole structure (X or Y)

i. One direct

connection from three 11KV Lightening Arrestors.

ii. Another direct

connection from the LT lightening Arrestors if provided.

(B) To each of the remaining two earth

electrodes.

i. One separate

connection from neutral (on the medium voltage side) of the Transformer (Two

wires)

ii. One separate

connection from the Transformer body and the handle of the 11KV A.B switch (Two

separate body earths to tank)

iii. One separate

connection from the Earthing Terminal of poles.

(C) 4mm G.I wire should be used for earth

leads.

JOINTS

·

There shall be

minimum joints preferably no joints enroute to earth electrodes

·

Where Joints are

unavoidable, they shall be brazed, rivetted or welded (and painted with red

lead and alluminium paints one after the other and finely coated with bitumen)

TOWER LINE GROUNDING

1) Ground rods are driven at the base of the tower. Where

it is not feasible, an electrode is located within a distance of 200 ft. of the

tower and grounding rods are provided at that point and tied to the tower base

by a single buried wire.

2) If low resistance is not obtained with 200ft, crowfoot

counterpoise with 4 wires is installed. The counterpoise conductors shall be 6

SWG galvanised steel wires taken away from the tower at mutually right angles

and kept atleast 50ft apart. Each of these wires is terminated at a rod at the

nearest point where low resistance is obtained. If counterpoise wires cannot be

terminated within half span from the tower the wire is carried through a

continuous counterpoise to the next tower, where the procedure is repeated.

Measurement of Earth Resistance

The

measurement of earth resistance is done using three terminal earth meggars or

four terminal earth meggars.

Three Terminal: Two temporary

electrodes or spikes are driven one for current and the other voltage at a

distance of 150 feet and 75 feet from the earth electrode under test and ohmic

values of earth electrode is read in the meggar.

Four Terminal: Four spikes

are driven into the ground at equal intervals. The two outer spikes are

connected to current terminals of earth meggar and the two inner spikes to

potential terminals of the meggar till a steady value is obtained.

Maintenance of Earthing System

The following Maintenance schedule

in mandatory at each of the Substations

|

Sl.No

|

Item

|

Periodicity

|

|

1.

|

Watering of Earth Pits

|

Daily

|

|

2.

|

Measurement of earth resistance of individual earth pits

|

Half yearly @

|

|

3.

|

Measurement of combined earth resistance at all the pits

|

Half yearly...

|

|

4.

|

Checking of inter connections between earth pits and tightness of

bolts and nuts

|

Quarterly

|

@

Earth resistance of individual earth pits can be measured by disconnecting the

earth connections to the electrode. This is possible if the connections are

made to a common clamp which is in turn is fixed round the pipe.

Combined earth resistance shall be the same at every earth pit unless it gets

disconnected from the earth mat

Definitions of General Earthing Terms

Soil Resistivity: This is the resistivity of a typical sample of soil

Earth Surface Voltage: The voltage

between a specified point on the ground around the rod and reference earth.

Earth Electrode

These are conductors, which are in

direct contact with the soil and provide the conductive part in electrical

contact with earth. They can include rods, tape, steel reinforcing bars.

Definitions of Terms associated with Power Systems

Neutral Point

The common point of a star connected

poly phase system or the earthed mid-point of a single phase system.

Independent Earth Electrode

An earth electrode located at such a

distance from other electrodes that its electrical potential is not

significantly affected by electric currents between Earth and other electrodes.

Exposed Conductive Part

Conductive part of equipment and

which is not normally live, but which can become live when basic insulation

fails.

Points of Earthing

1. Earth mat of 75 x 8 MS flat should be laid as outer of

the switchyard compulsorily and see that the pole structures are enclosed in

the outer mat.

2. Make vertical and horizontal sections for the outer

mat as shown in the fig. The internal vertical and horizontal sections may be

75 x 8 or 50 x 6 MS flat.

3. The Earth mat should be laid minimum 600MM, below the

ground level under the Earth mat and Bentonite powder is to be laid upto 25mm

and over the earth mat. The same Bentonite compound with Black cotton soil a

mixture of 1:6 ratio is to be placed upto 100 mm and the remaining earth trench

is to be back filled with the soil.

4. See that each and every pole structure is earthed with

50 x 6 MS flat to the Earth Mat.

5. For every breaker there will be fine earth connections

to the earth mat with 50 x 6 MS flat (a) Breaker body (b) Relay Panel (c) CT’s

of the Breaker (d) and two sides of the breaker structure.

6. Lightening arrestor is to be connected one end

directly to the earth mat and the other end is to the nearer earth pit or to

the earth mat.

7. Line Isolators are to be connected directly to the

earth mat.

8. The Power transformer body is to be connected two

sides to the earth mat.

9. Twin neutral earthing should be done to Power

Transformer as shown in the fig. one Earth flat of size 75 x 8mm M.S flat is

directly connected to the earth pit and the earth pit is again connected to the

Earth mat. The second neutral is directly connected to the earth mat,

10. Provide flexible jumpers thoroughly brazed as shown in

figure

11. All AB switches operating rods are to be provided with

coil earths and the AB switch support is to be earthed to the earth mat.

12. All the exposed earth flat which is dropping down from

the breakers, CT’s structures should be applied with bituminous paint.

13. 75 x 8 MS flat is to be

laid around the control room from main earth and the panels of the breakers,

midpoint of the Battery and Battery stand

structures are to be earthed to the earth flat and make a section in front of

the control room.

14. The

distance between any two earth electrodes should be twice the length of the

Electrode.

15. The

cable (11 x 33KV) sheaths are to be earthed with 25 x 3 GI strip to the Earth

mat.

16. The

neutral of the station transformer is to be connected to the Earth mat directly

with 25 x 3 GI strip. The body of the

Station transformer two sides to be connected to the earth mat with 25 x 3 GI

strip.

17. All the

welding joints should be painted with bituminous paint.

No comments:

Post a Comment